TITAN 7 WHEEL TECHNOLOGY

TITAN 7 FORGING PROCESS | Not all wheels are created equal.

BEST

Forged Process ›

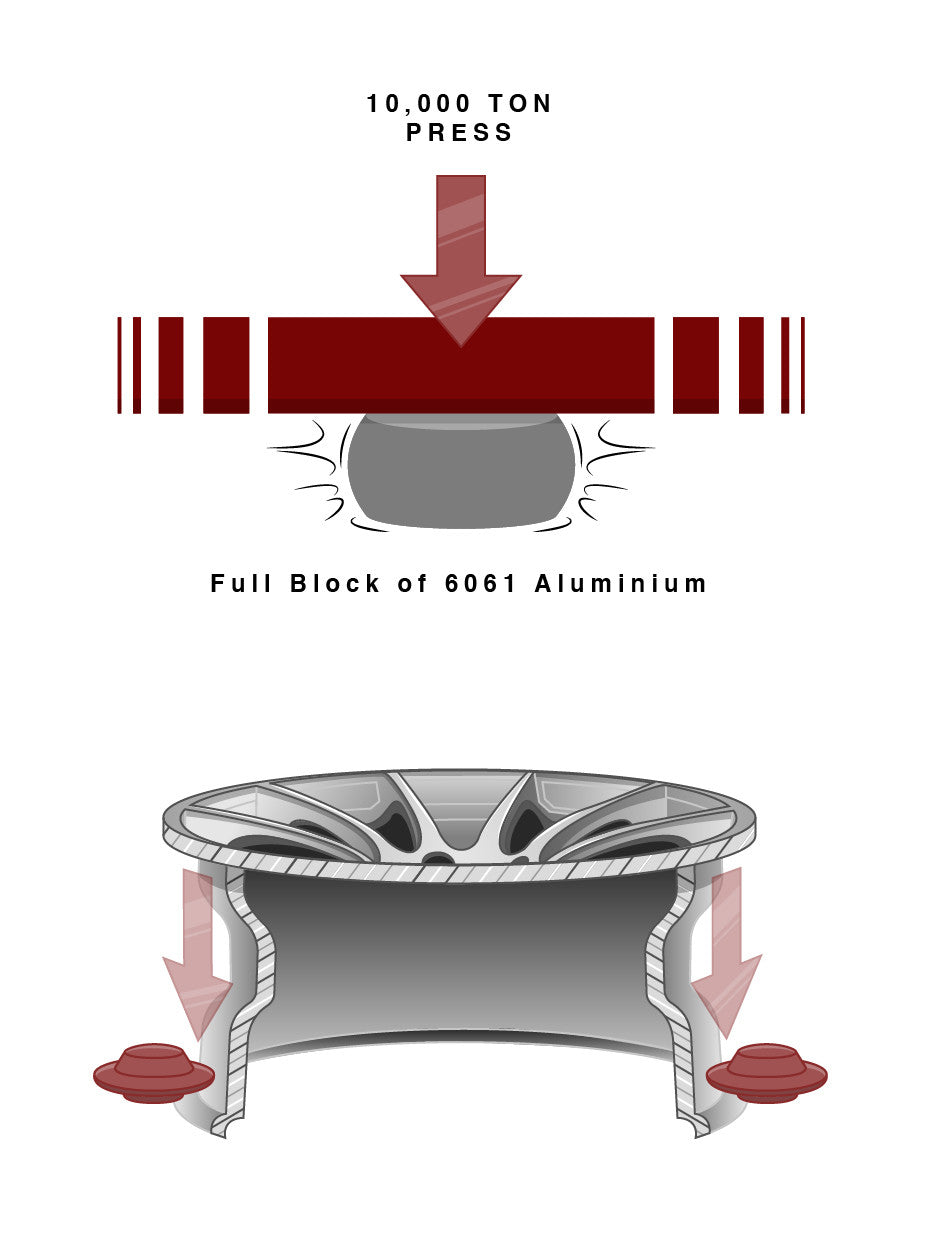

All Titan 7 Wheels are Fully Forged. The wheel starts out as an aircraft grade solid cylinder of 6061 Aluminum. We pressurize the cylinder with an industry leading 10,000 tons of pressure to give the wheel its basic shape while improving the grain structure and overall properties of the high grade aluminum. Absolutely no porosity and a densely organized microstructure to allow for amazing designs, weight, and strength.

STANDARD

Casting Process ›

Most wheels in the world are manufactured using this method. Molten aluminum (A356) is poured into a mold to create the complete wheel shape. It’s the cheapest method to make wheels and its pretty adequate for the street as long as it is made well. However, when it comes to performance / track settings the potential porosity of the wheel, especially on lower end cast wheels may cause cracks which is dangerous. Imagine pouring pancake batter into a bowl, you see air bubbles form.

BETTER

Flow Formed Process ›

Flow forming is popular today due to the increased density of the wheel rim that is spun forged like a vase. Pricing is still within the budget of most race / track enthusiasts. The issue is that a flow formed wheel starts out as a casting with a casting grade aluminum (A356). There is still potential for porosity, but it is a definite improvement over a completely casted wheel.

FEA ANALYSIS

Titan 7 employs state of the art in house product planning to give our customers the best product possible at the right price and also in a timely fashion. At the center of this is Finite Element Analysis (FEA) which helps us to validate a wheel design.

We can design a wheel structure, and then test in software how our design reacts to real world forces before we test the wheels physically in the lab or on the track.

TITAN 7 FACTORY TOUR

The key to Titan 7 Forged Wheels is that we make all of our wheels 100% in house. Everything from design, tooling, forging, machining, heat treatment, surface finishing, and testing is all done in house with no outsourcing. Very few Forged wheel companies can make this claim. This means you get complete quality and performance control.

We utilize an industry leading 10,000 TONS of pressure to form our wheels – You will get a perfect blend of strength, lightness, durability in the same product. That is why we are obsessive with lightness while we offer to you a lifetime structural warranty.

TITAN 7 FORGED WHEEL FEATURES

Gear Cut Knurled Bead Seat ›

All Titan 7 Forged wheels feature a gear cut knurled bead seat which improves the bind between the tire and the rim. This prevents tire creep / slippage and improves traction in high performance driving conditions.

Rigid Spoke Tracer ›

Titan 7 Forged Wheels feature structural improvements to basic designs such as the Rigid spoke tracer. This improves the stiffness and durability of the wheel while keeping the weight of the wheel to a minimum. Improving stiffness is key because if you can withstand wheel deflection / deformation in high load situations, you can improve driving consistency, which in turn leads to better confidence when on track.

Optimized Weight Reduction ›

Painstaking care was taken in removing as much material possible while keeping material in critical areas to ensure complete safety and reliability. All areas of the wheels are considered and tested with FEA Analysis software and tested in both laboratory and real world conditions.

Reinforced Inner Rim Flange ›

An example of how material is removed while key areas retain mass. In this case, we added forged mass to the inner rim to resist impact and bending.

Big Brake Clearance Compatibility ›

We have partnered with some of the world’s premier aftermarket Big Brake kit suppliers and made sure that we clear your potential racing upgrades. All wheels are designed to clear from the design phase while maintaining max concave and good looks. Notice the raised rim barrel which allows for large diameter rotor and caliper combos.

Max Fitment Every time ›

We build wheels application specific. No wheels are thought to be set up for multiple cars like most manufacturers. We take into account the proper performance wheel and tire size and the aesthetic of the car to make sure that you not only perform good, you look good. Our 100% in-house production capability allows for this.